LED bulbs with fans

LED headlight bulbs with fans utilize external sources to transfer heat, effectively accelerating heat dissipation. This cooling method is one of the most efficient ways to maintain optimal performance while ensuring maximum output.

The fan is integrated into the heat sink, making the design both stable and durable. This setup allows for more effective heat management, ensuring that the LED bulb operates efficiently and maintains consistent brightness over time.

our products

Explore LEZEN Led bulbs with fans Collection

Comprehensive Manufacturing and Machining Capabilities To Meet All Your Unique Needs

h11 led bulb with fan

L18 led headlight

1 copper pipe

12v/24v

High beam / low beam

h4 led bulb with fan

L19 led headlight

double copper pipes

12v/24v

High beam / low beam

h7 led bulb with fan

L24 LED Headlight

copper plate

12v/24v

High beam / low beam

h7 led bulb with fan

M32 led headlight

Color changed 3000k & 6500k

3copper pipe

12v/24v

High beam / low beam

h7 led bulb with fan

M38 led headlight

3 copper pipe

12v/24v

High beam / low beam

M35 LED Headlight

4 copper pipes &

12v/24v

High beam / low beam

h1 led bulb with fan

V12 LED Headlight

double copper pipes &

12v/24v

High beam / low beam

h7 led bulb with fan CANBUS

V8 led headlight

CANBUS

2 copper pipe

12v

High beam / low beam

h4 led bulb with fan CANBUS

V4 led headlight

copper plate

12v

High beam / low beam

Professional Car Lighting Solutions

LEZEN Applications Illuminate led headlight with fans

Reliable Lighting Solutions for Every Challenge

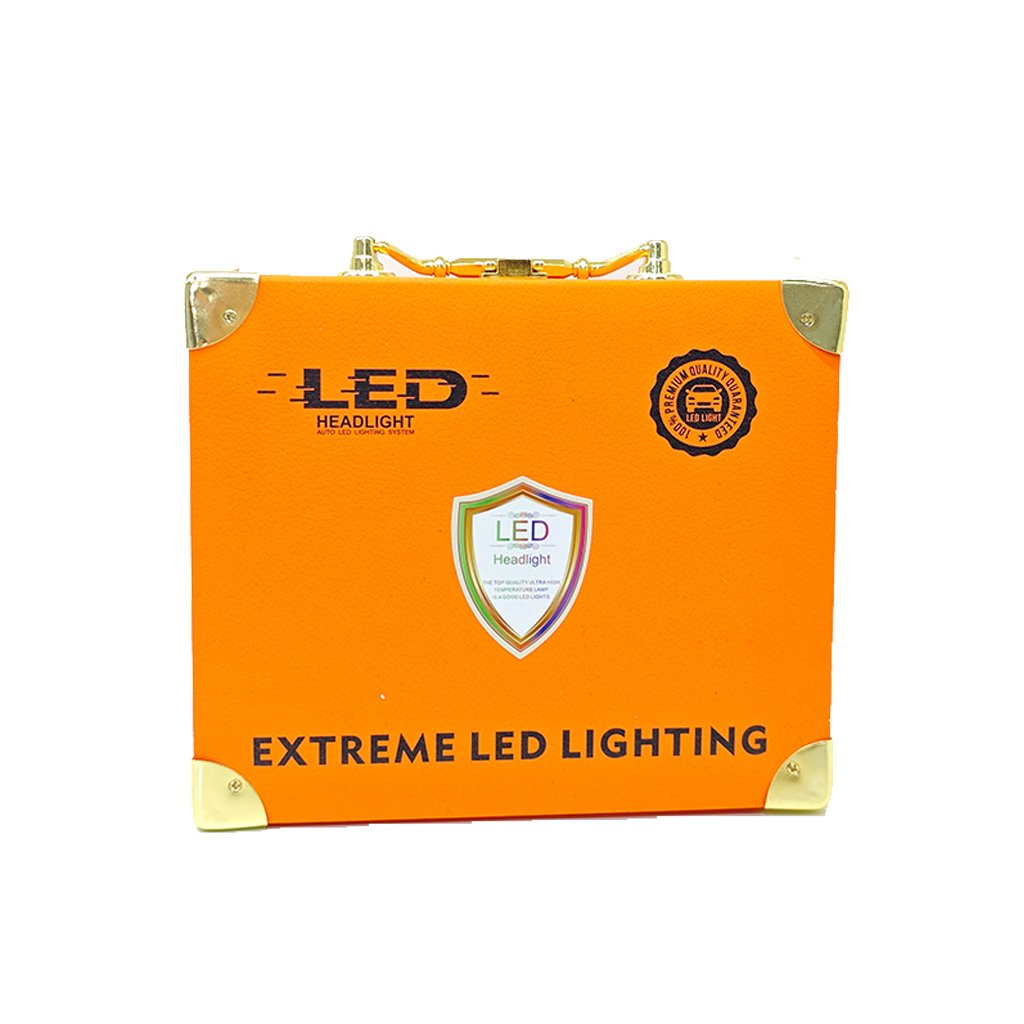

Our Customization Options For Your Needs

lezen lighting provides you with the best OEM/ODM service, you can easily customize your logo, package, color temperature, product appearance with low MOQ and competitive prices.

Customized packaging

One-Stop wholesale service

Automotive lighting wholesale can be easy. LEZEN Lighting has been wholesaling automotive bulbs for 15 + years and helps customers in more than 42 countries to be successful and get more profits. We are warmly welcome you would like become our distributor in your country.

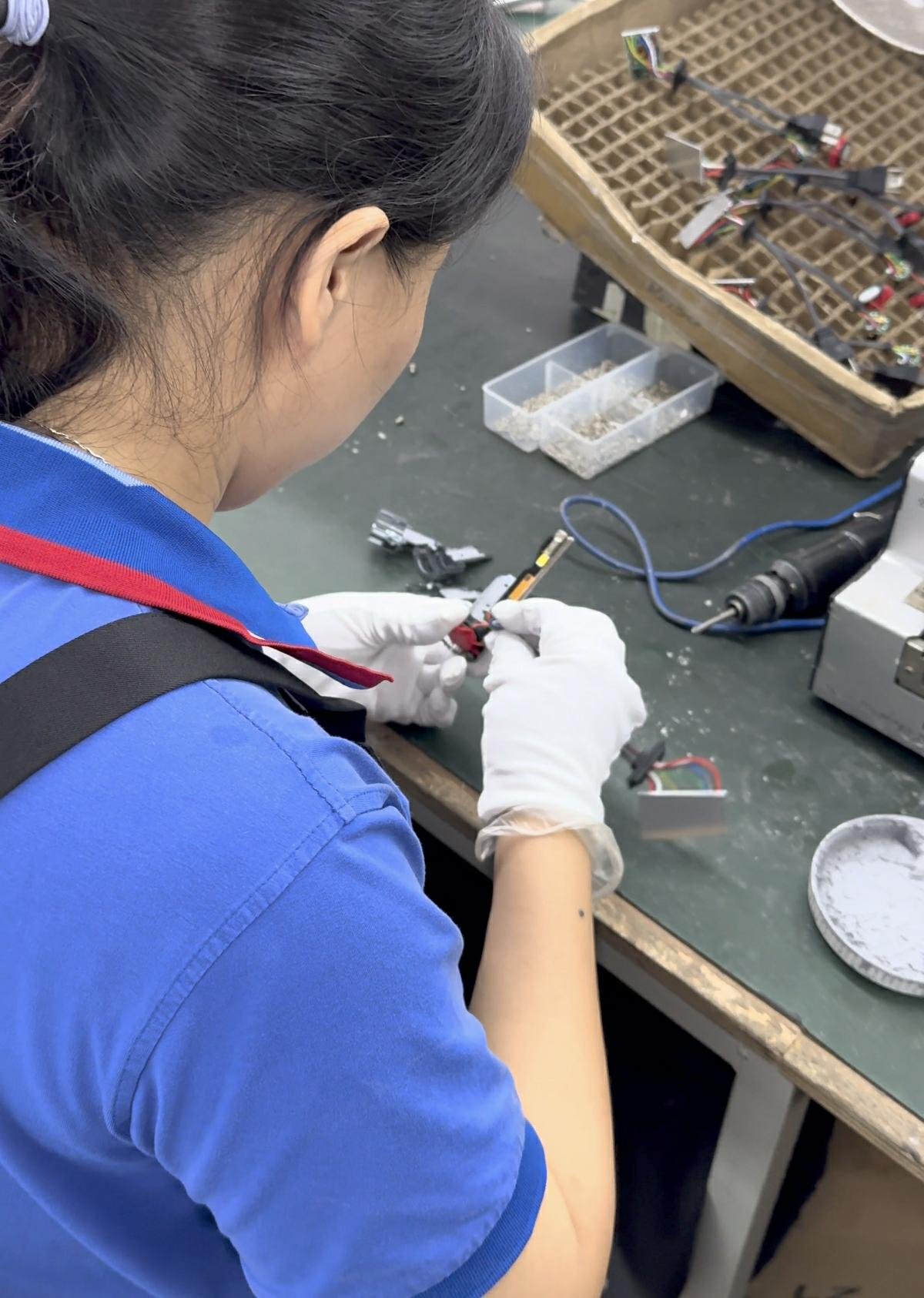

prodution line

how we made automotive LED bulb

Our production and inspection processes are fully automated. This helps us to produce accurate products and improve our qualification rate. you buy our products with confidence.

Step 1:Research & Development

Develop and optimize LED headlight bulb technology, focusing on light efficiency and heat dissipation.

Step 2:Incoming Material Inspection

Check the quality of LED chips, circuit boards, drivers, fans, and other components to ensure they are defect-free.

Step 3:SMT Placement

Use SMT technology to precisely mount LED chips onto the circuit board, ensuring circuit stability.

Step 4:Thermal Paste Application & Light Source Assembly

Evenly apply thermal paste to the positioning slot to enhance heat dissipation.Assemble the LED light source and secure the copper base plate for better durability and thermal conductivity.

Step 5:Driver Installation & Soldering

Manually solder the driver to ensure stable electrical connections.Solder and install the fan to optimize heat dissipation.

Step 6:Comprehensive Inspection & Aging Test

Conduct a full inspection of the LED headlight bulb to verify brightness, color accuracy, and stability.Perform a 72-hour aging test to ensure long-term reliability.

Step 7:Cleaning & Branding

Clean the bulb surface to remove dust and residues from the manufacturing process.Use laser engraving to print the brand logo, enhancing product recognition.

Step 8:Packaging & Shipment

Place the bulbs into protective packaging with manuals and product certifications. Ensure secure packaging and prepare for shipment.

Every Material is Tested to Ensure Quality

Aluminum Parts Inspection

To ensure aluminum parts meet quality standards for durable and reliable LED headlights.

Luminous Flux Testing

Testing luminous flux to ensure optimal brightness and performance of the LED headlights.

High-Temperature Resistance Testing

Testing for high-temperature resistance to ensure durability and reliable performance under extreme conditions.

Precision Testing

Testing for precision to ensure every detail meets the highest standards for optimal performance.

Performance Testing

Simulating voltage to test the bulb's power and other performance metrics.

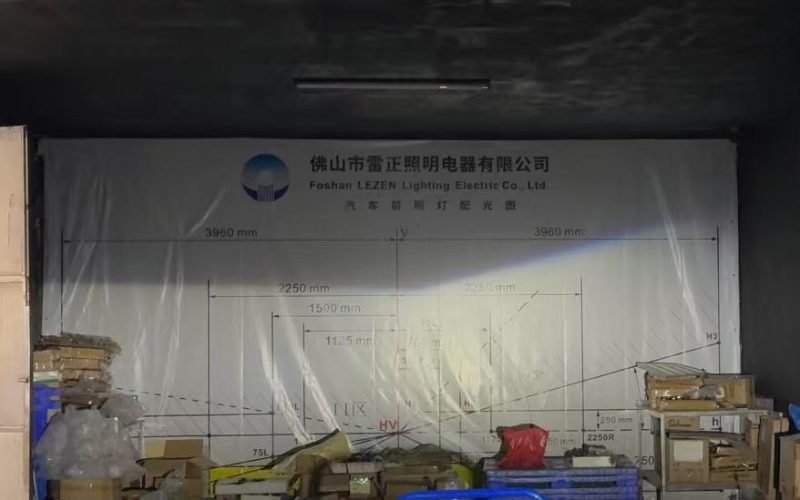

Beam Pattern Testing

Testing the light output for optimal brightness and beam pattern.

Bulb Aging Test

Aging Test for Bulbs to Verify Long-Term Performance and Reliability.

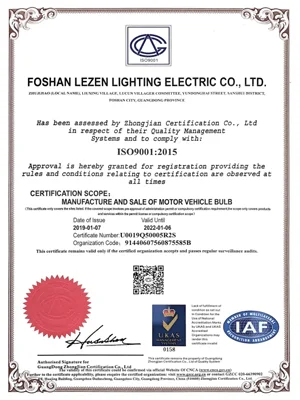

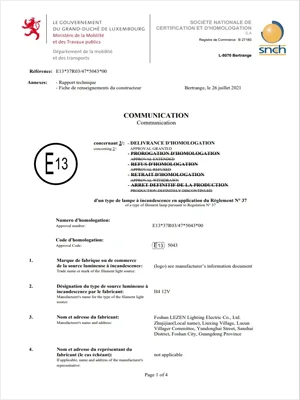

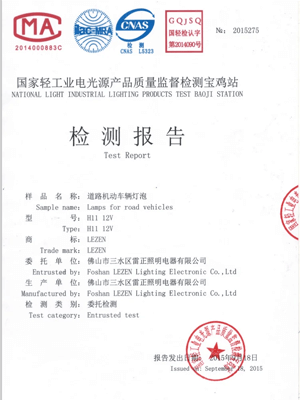

LEZEN Certification

ISO9001:2015 Certification

100+ Widgets

R37 EMARK Certification

250+ Widgets

TUV 16949 Certification

125+ Widgets

PRODUCT QUALITY TEST Certification

175+ Widgets

Why Choose LEZEN Lighting for Wholesale LED Car Bulbs?

LEZEN Lighting has been a trusted manufacturer of LED car lights since 2010, offering high-quality products, competitive pricing, and comprehensive support for wholesalers.

Guaranteed Quality & Competitive Pricing: We manufacture high-brightness, durable LED bulbs in our Foshan factory, strictly following ISO 9001 standards. With an independent factory, we offer premium products at competitive wholesale prices, maximizing customer profits.

Flexible Customization: We provide custom logos, packaging, light colors, and designs, helping businesses build unique brand identities.

Diverse Product Range: Our lineup includes high-power and low-power LED bulbs, as well as motorcycle and halogen bulbs to meet various market demands.

Global Distributor Support: We offer exclusive benefits for international distributors, ensuring quality products and services worldwide.

A Key Factor for Your Business Success

LED Car Bulbs: Fan vs. Fanless vs. Halogen – What's the Difference?

When choosing LED car bulbs, one of the key considerations is whether to opt for a fan-cooled or fanless design, or to stick with traditional halogen bulbs. Below is a comparison of these three types of lighting solutions, highlighting their key features and differences.

| Feature | Fan-Cooled LED (Our Solution) | Fanless LED | Halogen |

|---|---|---|---|

| Light Output | 6,500LM (Constant Current Driver Chip) | 4,800LM (Initial Brightness) | 1,500LM |

| Power Efficiency | 38W (LED + Dual Fans) → 171LM/W | 32W (Pure LED) → 150LM/W | 60W → 25LM/W |

| Thermal Management | Copper Base + Turbo Fan (Thermal Conductivity: 95W/m·K) | Aluminum Heat Sink (Thermal Conductivity: 220W/m·K) | Passive Cooling (Glass Shell) |

| Noise Level | <25dB (Lab-Tested) | 0dB | 0dB |

| Lifespan (L70) | 50,000 hours (Tj≤85°C) | 30,000 hours (Tj≤105°C) | 800 hours |

| Failure Rate | 0.8% (5-Year Warranty) | 5.2% (Due to Cooling Failure) | 18% (Filament Breakage) |

| Maintenance Cost | Modular Fan Design (Replacement Cost $1.2) | Full Unit Replacement | Frequent Replacement |

Fan-cooled LED bulbs provide superior brightness, power efficiency, and longevity, making them an excellent choice for drivers looking for long-term performance and reliability. Fanless LED bulbs offer silent operation but may suffer from higher thermal stress, reducing their lifespan. Traditional halogen bulbs, while inexpensive, have lower brightness, poor energy efficiency, and a significantly shorter lifespan.

For those seeking a balance between performance and cost-effectiveness, fan-cooled LED bulbs remain the optimal solution.

Request Quote Now !

Our proficient engineers and designers are ready to partner with you in developing the ultimate personalized shipping experience.